of electrical insulating

materials

Khotkovo city, Zavodskaya st., h. 21, b. 1

Our production

Composite electrical insulation materials based on mica papers

Mostly wide spread area of application of the composite materials based on mica papers is insulation of DC and AC traction motors and other electrical machines. Flexible mica based materials are applied as inter-phase and slot insulation. Molding materials based on mica papers are intended for manufacture of v-rings for traction motors commutators, and rigid sheets made of mica paper are applied for bar-to-bar insulation of traction motors commutators.

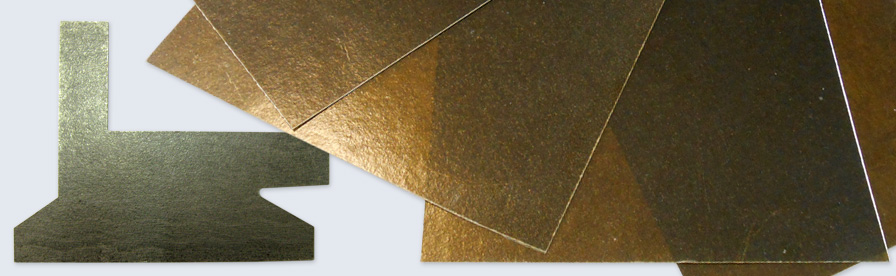

Rigid sheets for commutator insulation:

Used as insulation segment plates between copper plates in commutator of DC motors.

| Name | Composition | Thermal class | Thickness range, mm |

| KIFE | Mica paper + epoxy resin | F | 0,4-1,5 |

| KIFE-А | Mica paper +Glass cloth + epoxy resin | F | 0,4-1,5 |

| KIFE-H | Mica paper + epoxy resin | H | 0,4-1,5 |

| KIFE-H-А | Mica paper + Glass cloth + epoxy resin | H | 0,4-1,5 |

Mica laminates for molding products and parts:

These materials consist of mica paper combined with glass cloth and/or polymer film and impregnated by resin in B-stage. The laminates are usually applied in electrical machines and mechanisms as molding materials to produce different kinds of parts such as commutators v-rings, gaskets and others.

| Name | Composition | Thermal class | Components mass content, % | Thickness range, mm | ||

| Volatiles, max. | Inorganic part, min. | Binder | ||||

| FIFP-TPl | PET/ Mica paper /Glass cloth | F/H | 3,0 | 65,0 | 14-20 | 0,20-0,50 |

| FIFP-Pl | PET/Mica paper | F/H | 3,0 | 50,0 | 14-20 | 0,20-0,50 |

| FIFP-Т | Mica paper / Glass cloth | F | 3,0 | 65,0 | 14-20 | 0,20-0,50 |

| FIFK-АPm | PI-film/Mica paper | H/C | 3,0 | 65,0 | — | |

| FIFP-TPl | PET/ Mica paper /Glass cloth | H/C | 3,0 | 65,0 | - | |

| МК-18 | PET(PI)film / Mica paper/ Glass | C | 10,0 | - | 10±5 | 0,20-0,30 |

Flexible mica laminates:

The flexible laminates are the combination of mica paper with different kinds of polymer films and glass cloth as the armature layer. This kind of materials is used as slot and inter-phase insulation in electrical machines and traction motors.

| Name | Composition | Thermal class | Components mass content, % | Thickness range, mm | |

| Mica, min. | Volatiles, max. | ||||

| GSP-F-2Pl | PET / Mica paper / PET | F | 30,0 | 1,5 | 0,13-0,60 |

| GSP-F-Pl | PET / Mica paper | F | 30,0 | 1,5 | 0,13-0,60 |

| GSP-F-TPl | PET/ Mica paper / Glass cloth | F | 30,0 | 1,5 | 0,13-0,60 |

| GSP-H-2Pl | PEN(PI) / Mica paper / PEN(PI) | H | 30,0 | 1,5 | 0,13-0,60 |

| GSP-H-Pl | Mica paper / PEN (PI) | H | 30,0 | 1,5 | 0,13-0,60 |

| GSP-H-TPl | PEN(PI) / Mica paper/ Glass cloth | H | 30,0 | 1,5 | 0,13-0,60 |

Moisture-resistant flexible mica laminates:

These laminates consist of mica paper combined with glass cloth and polymer films by epoxy-polyester or silicone resin. The materials are used slot, inter-phase and inter-layer insulation in insulation systems of electrical machines working in wet conditions. Can be processed with significant technological pressures on materials.

| Name | Composition | Thermal class | Components mass content, % | Thickness range, mm | |

| Inorganic part, min. | Volatiles, max. | ||||

| GIP-Т-SPl(v) | Glass cloth/ Mica paper / Glass cloth/ PET-film + epoxy-polyester resin | F | 40,0 | 1,5 | 0,25-0,40 |

| GIP-ТS(v) | Glass cloth/ Mica paper /Glass cloth + epoxy-polyester resin | F | 40,0 | 2,0 | 0,25-0,50 |

| GIK-Т- SPl(v) | Glass cloth/ Mica paper /Glass cloth/ PET-fim + silicone resin | H | 55,0 | 1,5 | 0,25-0,50 |

| GIK-ТS(v) | Glass cloth / Mica paper /Glass cloth + silicone resin | H | 68,5 | 1,5 | 0,25-0,50 |

Arc-resistant and interlayer mica content laminates:

Applied in insulation structures of electrical machines and mechanisms as an electric insulation material of gaskets, washers and construction materials.

| Name | Composition | Thermal class | Thickness range, mm |

| Interlayer mica content laminate PSE | Mica+ binder | F | 0,15-5,0 |

Flexible mica laminates resistant to high temperatures:

These laminates consist of muscovite or phlogopite mica paper combined of one or both sides with glass cloth and impregnated with silicone resin. Used as slot, interturn or interphase insulation of electric machines operating under high temperatures.

| Name | Composition | Thermal class | Components mass content, % | Thickness range, mm | ||

| Mica, min. | Volatiles, max. | Binder | ||||

| G1SK | Mica paper/Glass cloth | H | 40,0 | 2,0 | 25-40 | 0,10-0,15 |

| G2SK | Glass cloth / Mica paper/Glass cloth | H | 40,0 | 2,0 | 25-40 | 0,20-0,35 |

| G1SKN | Mica paper/Glass cloth | C | 40,0 | 2,0 | 25-40 | 0,10-0,15 |

| G2SKN | Glass cloth / Mica paper/Glass cloth | C | 40,0 | 2,0 | 25-40 | 0,20-0,35 |

| GSKV | Mica paper/Glass cloth | C | 40,0 | 2,0 | 30 | 0,10-0,15 |

| Fleksimid 942 | Glass cloth/ Phlogopite mica paper / PI | C | 0,13-0,50 | |||